- Phone:+86 15218629499

- Phone: +86 15766990063

- E-mail: Yzprinting01@163.com

In today's fast-paced consumer environment, the demand for efficient and reliable packaging solutions has never been greater. According to a recent report by MarketsandMarkets, the global plastic packaging market is projected to reach USD 650 billion by 2025, driven by rapid urbanization and increasing consumer preferences for convenience. Within this booming sector, "packing bag plastic" has emerged as a versatile option, catering to diverse applications across industries, from food and beverages to pharmaceuticals. The right selection of plastic packing bags not only ensures product integrity but also plays a critical role in enhancing brand image and customer satisfaction. This ultimate guide will explore essential criteria to consider when choosing plastic packing bags, helping businesses navigate the myriad of options available to meet their specific needs effectively.

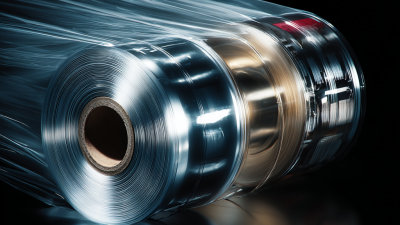

When it comes to selecting the right plastic packing bags for various applications, understanding the different types available is crucial. Plastic packing bags come in a myriad of forms, each designed for specific uses. For instance, polyethylene bags are widely used for their versatility and durability, making them a popular choice for everything from grocery shopping to packaging food items. Polypropylene bags, on the other hand, are preferred for their higher clarity and strength, often utilized in retail packaging and product displays.

As the market evolves, there's a growing demand for eco-friendly alternatives, particularly biodegradable options. Consumers are increasingly asking for sustainable packaging solutions, which has led manufacturers to innovate with materials that reduce environmental impact. The introduction of biodegradable plastic packing bags caters to this need, enabling businesses to meet consumer preferences while also aligning with environmental regulations. With the global plastic packing bag market projected to grow significantly, understanding these options is essential for selecting the right product to meet your packaging needs.

When selecting the right plastic packing bag, sustainability should be at the forefront of your considerations. With the increasing awareness of environmental issues, it's essential to choose bags that minimize waste and promote eco-friendly practices. Factors such as material type play a critical role—opting for biodegradable or recyclable materials like polyethylene (PE) or polypropylene (PP) not only supports responsible consumption but also influences the overall market trends towards more sustainable solutions.

Moreover, the design and closure type of the bag matter as well. Consider self-standing pouches or flat bags that cater to specific needs, while functionality—such as resealable closures—encourages reuse, further reducing plastic dependency. As consumer preferences shift towards more sustainable packaging, brands and manufacturers must adapt, reflecting the demand for innovation that aligns with eco-conscious values. Thus, ensuring that your plastic packing bag aligns with sustainable principles will not only meet your needs but also contribute positively to the environment.

As consumers and businesses increasingly prioritize sustainability, eco-friendly plastic packing options are gaining traction. According to a report by Smithers Pira, the global sustainable packaging market is projected to reach $900 billion by 2027, underscoring the demand for materials that reduce environmental impact. Eco-friendly plastic bags made from biodegradable or recycled materials not only meet consumer preferences but also help brands stand out in a crowded marketplace.

When selecting eco-friendly plastic packing bags, consider the types of materials available. Bags made from plant-derived materials, such as corn starch, are fully compostable and break down within a few months in industrial composting facilities. Alternatively, recycled polyethylene bags (rPET) can be reused multiple times, significantly lowering their environmental footprint compared to traditional virgin plastic bags.

**Tip 1**: Look for certification labels like the Biodegradable Products Institute (BPI) mark, which can help ensure the bags meet rigorous compostability standards.

**Tip 2**: Always check the recycling guidelines for your chosen material to understand how it can be disposed of responsibly. By making informed choices, you can align your packing solutions with sustainable practices, appealing to eco-conscious consumers.

| Type of Bag | Material | Biodegradability | Recyclability | Uses |

|---|---|---|---|---|

| Biodegradable Bag | PLA (Polylactic Acid) | Yes | Yes | Food Packaging, Retail |

| Recyclable Plastic Bag | HDPE (High-Density Polyethylene) | No | Yes | Grocery Bags, Merchandise |

| Compostable Bag | PBA (Polybutylene Adipate-Co-Terephthalate) | Yes | Limited | Organic Waste, Biodegradable Products |

| Standard Plastic Bag | LDPE (Low-Density Polyethylene) | No | Yes | General Purpose, Dry Goods |

When it comes to selecting the right plastic packing bags, proper measurement and sizing are crucial for ensuring functionality and efficiency. According to a report from the Flexible Packaging Association, nearly 30% of packaging waste results from inappropriate sizing. This not only leads to increased costs but also hinders product protection during transit. Therefore, accurate dimensions are paramount.

To measure your plastic packing bags correctly, start by determining the dimensions of your product. A common industry practice is to measure the length, width, and height, allowing for a snug fit without excessive material. For instance, if your product is 10 inches long, 5 inches wide, and 3 inches high, you should select a bag size that accommodates these measurements with a little extra space—often around half an inch more on all sides. This ensures the bag can comfortably hold the product while allowing for any additional cushioning materials that may be required, thereby enhancing protection during shipping.

Furthermore, understanding the various bag styles—such as flat bags, gusseted bags, or zipper bags—can influence your sizing decision. A study by Smithers Pira highlights that 41% of manufacturers prefer gusseted bags for bulkier items, as they offer increased volume while maintaining a compact form. By selecting the right type and size of plastic packing bag, businesses can not only protect their products effectively but also contribute to reducing waste and improving cost efficiency in their packaging operations.

When selecting plastic packing bags, many people make common mistakes that can lead to inefficiencies and dissatisfaction with their choices. One significant error is underestimating the importance of size. Choosing a bag that is too small can result in damaged contents, while an oversized bag can lead to unnecessary waste and increased shipping costs. Always measure your items and consider the size of the packing bag carefully to ensure a snug fit.

Another prevalent mistake is overlooking material quality. Not all plastic is created equal, and using subpar materials can compromise the safety and longevity of your items. Opt for bags made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE), as they offer better durability and protection against punctures and tears. Checking for thickness and certifications can also help ensure you select a bag that meets your needs.

Ultimately, another common pitfall is ignoring customization options. Many users settle for standard sizes and styles without considering the benefits of custom bags that cater specifically to their products. Investing in customized bags not only enhances your brand’s image but also ensures a perfect fit for your items, improving customer satisfaction. Take the time to explore these options before making a final decision.