- Phone:+86 15218629499

- Phone: +86 15766990063

- E-mail: Yzprinting01@163.com

In today’s competitive market, the choice of Packaging Roll Film can significantly impact a business's success. According to a recent industry report by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2024. This growth is largely fueled by the rising demand for sustainable solutions and innovative packaging designs. Yet, many businesses struggle to choose the right type of roll film that meets their specific needs.

Packaging Roll Film offers versatility and efficiency. However, not all options are created equal. Features like thickness, barrier properties, and printability can vary widely. Businesses often overlook these details, which can lead to wasted resources and missed opportunities. While brands aim for visually appealing packaging, the functionality often takes a backseat.

Investing in the right Packaging Roll Film is crucial. It influences shelf life, customer perception, and overall brand identity. Understanding the different types available is essential for maximizing value. As brands navigate through their options, they must reflect on their unique requirements and market trends, ensuring they select packaging that truly aligns with their goals.

When choosing packaging roll films, understanding the types and their applications is crucial. Flexible films account for about 34% of the global packaging market, according to recent industry reports. This segment includes various types, such as polyethylene (PE), polyvinyl chloride (PVC), and more. Each material has distinct features that suit different products. For example, PE is lightweight and moisture-resistant, ideal for food packaging. PVC, while more rigid, offers excellent clarity and is often used for shrink films.

Another popular choice is biodegradable films, which are gaining traction in eco-conscious markets. These films, while often more expensive, cater to consumers seeking sustainable options. A study by a leading market research firm indicated that 43% of consumers prefer products with eco-friendly packaging. However, companies must balance costs and consumer demands. Being sustainable can sometimes lead to higher production expenses, which can be challenging for smaller businesses.

In addition, thickness and printability are other critical factors. Thicker films provide better protection but may reduce flexibility. Conversely, thinner films often lead to printing challenges. Thus, businesses need to weigh these attributes against their specific needs. Overall, selecting the right roll film is not just about functionality but also about aligning with market trends and consumer preferences. Re-evaluating your film choices will make a lasting impact.

| Film Type | Material | Application | Moisture Barrier | Heat Sealability | Cost Efficiency |

|---|---|---|---|---|---|

| Polyethylene (PE) | LDPE, HDPE | Food packaging, industrial | Good | Moderate | Low |

| Polypropylene (PP) | BOPP | Snack food, cosmetics | Fair | Excellent | Moderate |

| Polyvinyl Chloride (PVC) | Rigid and flexible | Medical supplies, electronics | Excellent | Good | High |

| Paper | Kraft, coated | Gift wrapping, food service | Fair | Limited | Low |

| Aluminium Foil | Thin metallic | Food storage, pharmaceuticals | Excellent | Good | High |

| Barrier Films | Multi-layer | Coffee, snacks | Excellent | Excellent | High |

| Biodegradable Films | PLA, starch | Eco-friendly products | Good | Moderate | Moderate |

| Shrink Films | PVC, polyolefin | Bundling, display | Good | Excellent | Moderate |

| Stretch Films | Polyethylene | Pallet wrapping | Good | Limited | Low |

| Pouch Films | Multi-layer | Stand-up pouches, snacks | Excellent | Excellent | High |

When selecting packaging roll film for your business, several factors are crucial. One of the most critical considerations is material type. Polyethylene, polypropylene, and nylon are popular choices. Each material provides different levels of moisture barrier, puncture resistance, and clarity. According to industry reports, businesses often report a 15% increase in shelf life when using high-barrier films. Understanding the specific needs of your product can ensure you select the right film.

Another vital aspect is the film thickness. Thicker films generally provide better protection but can increase costs. Many manufacturers suggest a standard thickness between 50 to 100 microns for durable applications. However, overestimating thickness can lead to unnecessary costs. A balance must be struck. Additionally, sourcing from regional suppliers can reduce shipping time and costs, impacting production efficiency.

Finally, printability is essential. According to a recent market study, about 40% of consumers are influenced by packaging designs. The film must allow for high-quality printing to attract potential buyers. Yet, achieving the right balance between aesthetics and functionality can be challenging. Reflecting on these elements can lead to better decisions regarding packaging roll films.

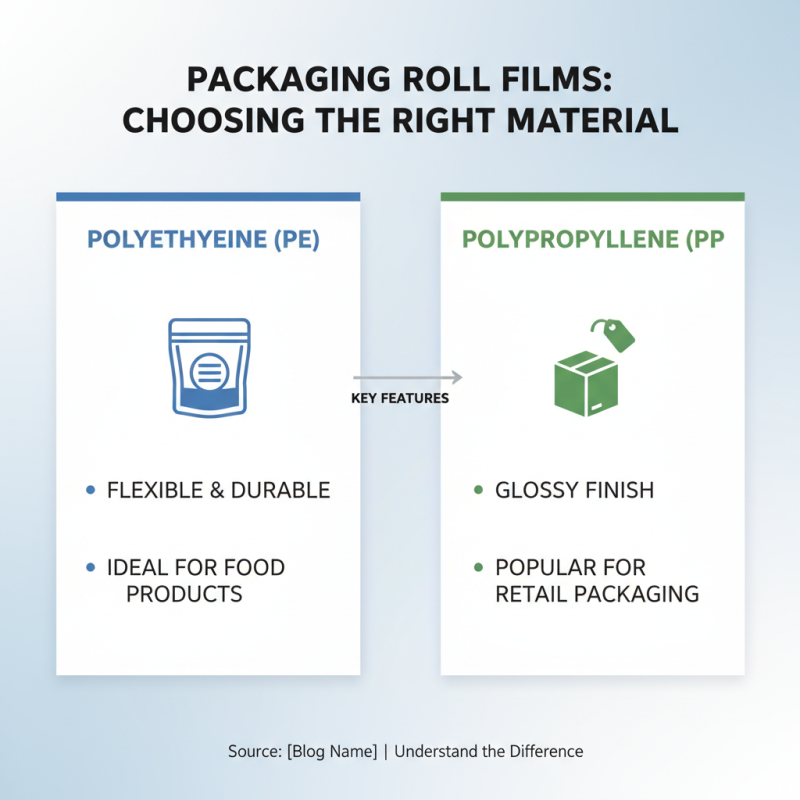

When choosing packaging roll films, understanding their unique features is crucial. Different materials serve different purposes. For example, polyethylene offers flexibility and durability. It’s often used for food products. On the other hand, polypropylene provides a glossy finish. This makes it a popular choice for retail packaging.

Among these options, biodegradable films are gaining popularity. They appeal to environmentally conscious businesses. However, their durability may not match traditional materials. Companies often need to balance sustainability with functionality. Then there are high-barrier films. They protect products from moisture and oxygen. This is vital for items like pharmaceuticals.

Budget constraints also play a role in selection. Some films might look attractive but can be expensive. It’s important to assess cost versus benefit. This will impact your bottom line. As businesses grow, they should re-evaluate their packaging choices. A film that works today may not suit future needs. Flexibility and innovation often dictate success in packaging.

Sustainability is becoming imperative in packaging. Eco-friendly roll films are gaining popularity. These materials reduce waste and enhance the green image of your brand. Many options are available, and choosing the right one can be challenging.

Consider using biodegradable films made from renewable resources. These films break down naturally, minimizing environmental impact. Additionally, look for films with lower carbon footprints. These options can help your business contribute to a healthier planet.

Tips: Always research the source of the materials. Understanding their lifecycle is essential. Engage with suppliers who prioritize sustainability. This communication fosters a relationship based on shared values. Reflect on the long-term benefits of moving towards eco-friendly packaging. Your commitment can make a difference in consumer perception.

As businesses adapt to changing consumer demands, packaging roll films are evolving. One notable trend is sustainability. Many companies are moving towards biodegradable or recyclable materials. This shift reflects a growing awareness of environmental issues. However, not all brands have made this transition. Some continue to use traditional plastics, which raises questions about their long-term strategies.

Another trend is customization. Businesses desire unique packaging that stands out on shelves. Advances in technology enable short-run printing. This allows for personalized designs without high costs. Yet, some companies struggle to balance efficiency and creativity. They may end up with generic packaging that fails to resonate with customers.

The digital transformation also plays a role. Automation in production lines is on the rise. Smart packaging solutions are being developed. They integrate technology to enhance user experience. But, there is a fine line between innovation and complexity. Too much technology can confuse consumers rather than attract them. As trends develop, businesses must remain vigilant. They should evaluate their choices carefully to stay relevant.