- Phone:+86 15218629499

- Phone: +86 15766990063

- E-mail: Yzprinting01@163.com

In today's fast-paced industrial landscape, Plastic Wrapper Packaging has emerged as a game-changing solution across various sectors, championing efficiency and sustainability. According to a report by Smithers Pira, the global market for flexible plastic packaging is projected to reach $339 billion by 2024, reflecting a compound annual growth rate (CAGR) of 4.2%. This growth is driven by the increasing demand for lightweight, durable, and cost-effective packaging solutions in food and beverage, pharmaceuticals, and consumer goods.

Originating from top manufacturing sites in China, these innovative packaging solutions not only elevate product preservation but also enhance brand visibility and customer experience. This blog delves into the transformative role of Plastic Wrapper Packaging in different industries, showcasing how it is successfully meeting modern challenges while building trust on a global scale.

Originating from top manufacturing sites in China, these innovative packaging solutions not only elevate product preservation but also enhance brand visibility and customer experience. This blog delves into the transformative role of Plastic Wrapper Packaging in different industries, showcasing how it is successfully meeting modern challenges while building trust on a global scale.

In the food industry, plastic wrapper packaging has transformed the way products are stored and distributed, ensuring freshness and safety. One innovative application is the use of vacuum-sealed packaging for perishable items such as meats and dairy products. This method reduces oxidation and bacterial growth, extending shelf life significantly. Brands increasingly rely on this technique not just for preservation, but for minimizing food waste, which is critical in today's environmentally conscious market.

Another exciting development is the incorporation of biodegradable materials into plastic wrapper packaging. Many manufacturers are adopting bio-based plastics made from renewable resources, which helps reduce the carbon footprint associated with traditional packaging. This shift not only appeals to eco-aware consumers but also aligns with global sustainability goals. Additionally, smart packaging technology—integrating sensors that monitor freshness and temperature—provides real-time feedback to both retailers and consumers, enhancing food safety and improving the overall user experience.

The shift towards sustainable practices in packaging is becoming increasingly critical as industries seek to address growing concerns about climate change and plastic pollution. Eco-friendly innovations in plastic wrapper packaging are at the forefront of this movement, offering solutions that not only minimize environmental impact but also enhance the overall efficiency of supply chains. Companies are now investing in research to develop sustainable materials that meet consumer demands while adhering to stringent environmental guidelines.

The shift towards sustainable practices in packaging is becoming increasingly critical as industries seek to address growing concerns about climate change and plastic pollution. Eco-friendly innovations in plastic wrapper packaging are at the forefront of this movement, offering solutions that not only minimize environmental impact but also enhance the overall efficiency of supply chains. Companies are now investing in research to develop sustainable materials that meet consumer demands while adhering to stringent environmental guidelines.

One noteworthy trend is the rise of upcycled materials in packaging, which is gaining traction as businesses prioritize Environmental, Social, and Governance (ESG) goals. This transition not only supports waste reduction but also aligns with the increasing consumer perception that values sustainability. Moreover, the development of sustainable antimicrobial and antioxidant packaging solutions demonstrates how the industry is innovating to address both health and environmental concerns simultaneously. As more businesses embrace these sustainable practices, they contribute to a circular economy that prioritizes resource efficiency and environmental stewardship, ultimately leading to a greener future for all industries involved.

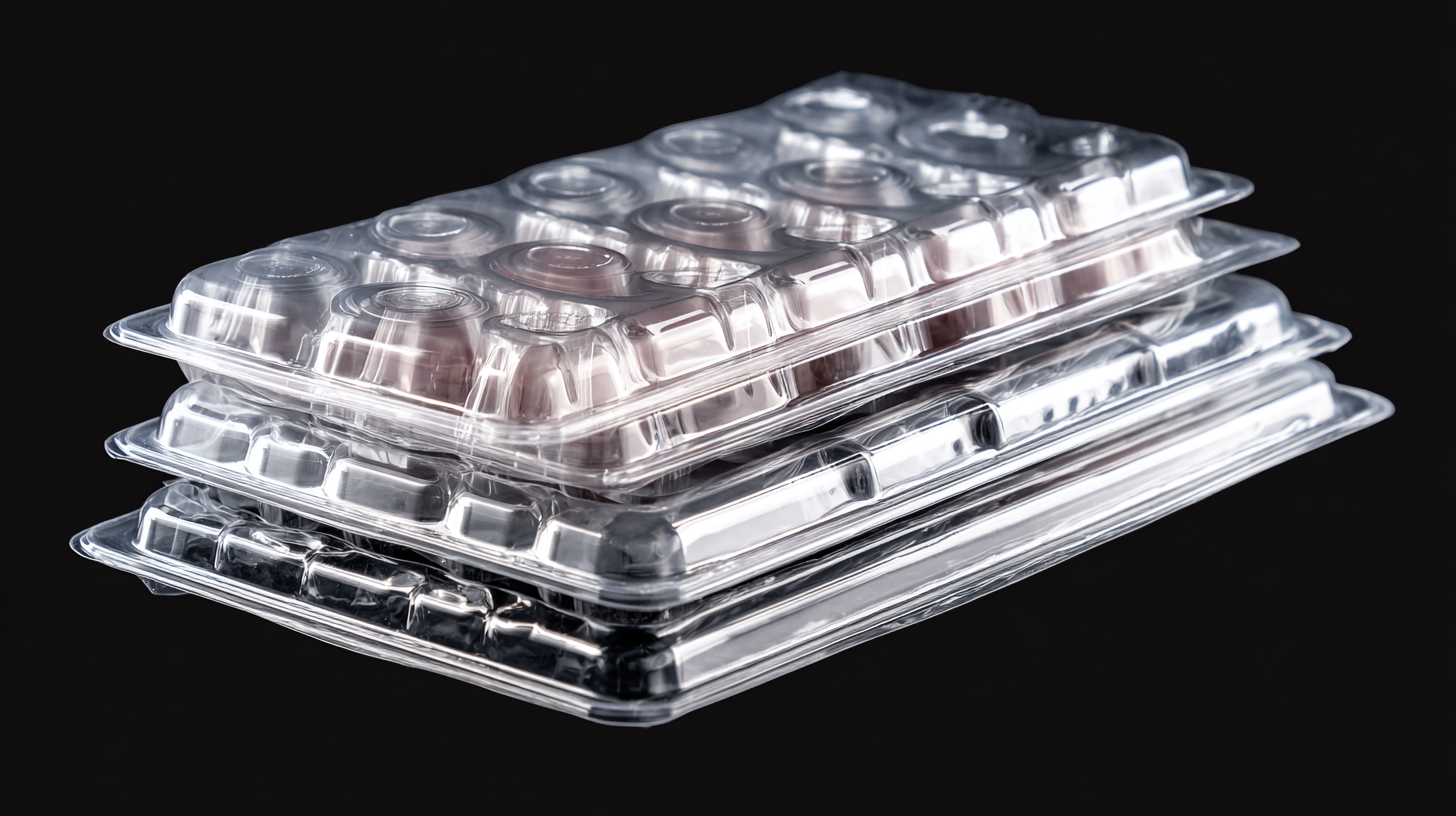

In the retail industry, the design of plastic wrapper packaging has a profound impact on customer experience, influencing purchasing decisions and brand loyalty. According to a report by Smithers Pira, the global market for flexible packaging is projected to reach $300 billion by 2024, demonstrating an increased reliance on innovative packaging solutions. Enhanced plastic wrapper designs, which incorporate functionality and aesthetics, can significantly elevate a product's visibility on the shelf and engage customers more effectively. For instance, transparent wrappers allow consumers to view the product directly, while vibrant colors and creative shapes capture attention and enhance brand identity.

Furthermore, the incorporation of sustainable materials and smart technology into plastic wrapper designs is revolutionizing the retail landscape. A 2022 study by Mintel highlighted that 72% of consumers are willing to pay more for products that use eco-friendly packaging. Retailers who adopt sustainable practices not only appeal to environmentally conscious shoppers but also position themselves as responsible leaders in the industry. Additionally, integrating QR codes or augmented reality features into packaging allows brands to provide interactive experiences, enabling customers to access product information, promotional offers, or loyalty rewards seamlessly. This combination of innovative design and technology creates a transformative shopping experience that strengthens consumer engagement and drives sales.

In the ever-evolving healthcare sector, packaging plays a critical role in safeguarding medical products and ensuring patient safety. The innovative use of plastic wrapper packaging has revolutionized how pharmaceuticals and medical devices are stored and transported. Utilizing advanced materials that offer both flexibility and durability, manufacturers can create packaging solutions that not only protect against contamination but also extend the shelf life of essential products. This is particularly important for vaccines and sensitive medications that require stringent storage conditions.

Moreover, the design of the packaging can greatly influence user experience and compliance. Child-resistant and easy-to-open features enhance safety while making it easier for caregivers to access medications. Additionally, significant advancements in labeling technology, such as QR codes and holographic seals, provide vital information about the products, including their origin, usage instructions, and expiry dates. By prioritizing innovative plastic wrapper packaging, healthcare providers can enhance the efficiency of medical services, improving outcomes for patients while meeting regulatory standards. This convergence of safety, functionality, and technological integration defines the future of packaging in the medical field.

| Application Area | Type of Plastic Wrapper | Benefits | Challenges |

|---|---|---|---|

| Medication Packaging | Blister Packs | Tamper-proof, dose control | Material compatibility, production cost |

| Surgical Instrument Packaging | Sterilizable Wraps | Maintains sterility, durability | Cost of sterilization, waste management |

| Diagnostic Kits | Flexible Pouches | Lightweight, space-efficient | Risk of puncture, storage capacity |

| Transfusion Bags | Polyvinyl Chloride (PVC) | Flexibility, safe storage | Recycling issues, plastic leaching |

| Personal Protective Equipment (PPE) | Polyethylene Films | Barrier protection, customizable | Breathability, durability in extreme conditions |

The future of plastic wrapper packaging is poised for significant transformation as industries adapt to emerging trends that prioritize sustainability and innovation. One major trend is the shift toward biodegradable and compostable materials, which meet consumer demand for eco-friendly solutions. Many companies are looking to develop wrappers that decompose naturally, thus minimizing their environmental impact while still providing the durability and protection required for products. This shift not only helps in reducing plastic waste but also enhances brand reputation among increasingly eco-conscious consumers.

In addition to sustainability, advancements in technology are paving the way for smart packaging solutions. These innovative wrappers can include features such as QR codes, NFC chips, and even sensors that monitor freshness and provide consumers with real-time information about product quality. This technology enhances the user experience by adding a layer of interactivity and convenience. As more industries embrace these trends, the landscape of plastic wrapper packaging is evolving, making it an exciting area to watch for future developments that prioritize both utility and environmental stewardship.