- Phone:+86 15218629499

- Phone: +86 15766990063

- E-mail: Yzprinting01@163.com

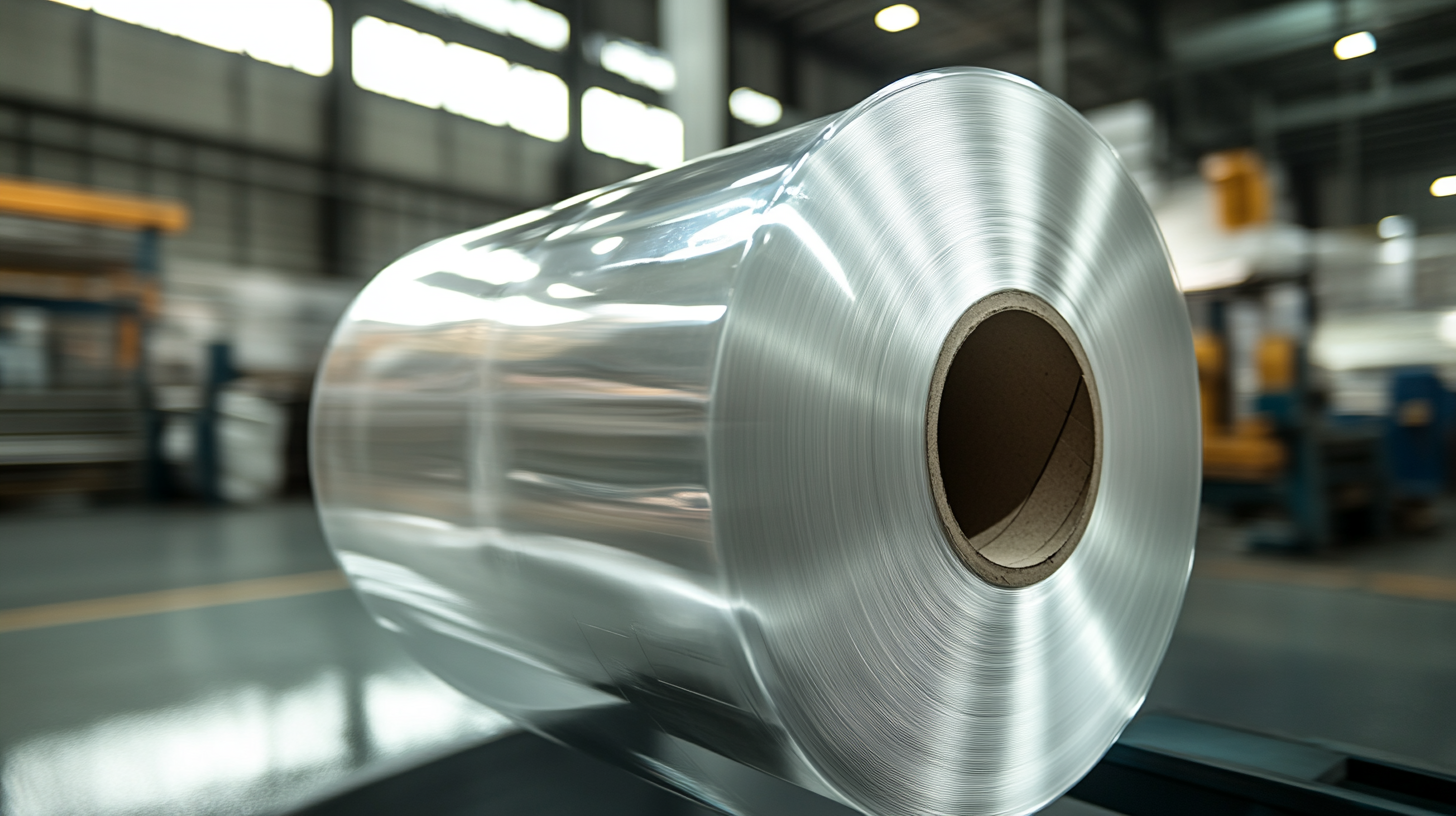

In recent years, China has emerged as a global leader in quality manufacturing, particularly in the realm of Film Roll Packaging solutions. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2025, with Film Roll Packaging accounting for a significant share due to its versatility and efficiency. As industries across the globe increasingly seek sustainable and cost-effective packaging options, China's advanced manufacturing capabilities and innovative approaches position it as a prime contributor to meeting these demands. With state-of-the-art technology and a focus on quality, Chinese manufacturers are not only enhancing the performance of Film Roll Packaging but are also setting new standards for the industry at large, making it essential for businesses worldwide to stay informed on these developments.

In recent years, China has emerged as a global leader in quality manufacturing, particularly in the realm of Film Roll Packaging solutions. According to a report by Smithers Pira, the global flexible packaging market is projected to reach $300 billion by 2025, with Film Roll Packaging accounting for a significant share due to its versatility and efficiency. As industries across the globe increasingly seek sustainable and cost-effective packaging options, China's advanced manufacturing capabilities and innovative approaches position it as a prime contributor to meeting these demands. With state-of-the-art technology and a focus on quality, Chinese manufacturers are not only enhancing the performance of Film Roll Packaging but are also setting new standards for the industry at large, making it essential for businesses worldwide to stay informed on these developments.

Quality manufacturing plays a pivotal role in the film roll packaging industry, as it directly influences the protection and integrity of the products within. In today’s global marketplace, the demand for high-quality packaging solutions is at an all-time high, driven by the need to ensure that film rolls—whether for photography, movies, or any other application—reach consumers in pristine condition. This underscores the necessity of rigorous quality control processes, innovative production techniques, and the use of premium materials that can withstand the rigors of transportation and storage.

Understanding the importance of quality manufacturing also extends to sustainability and efficiency. Manufacturers in China are at the forefront of adopting advanced technologies that not only enhance production quality but also minimize waste and environmental impact. By prioritizing quality, companies can establish strong brand reputations and foster customer loyalty, which is essential in a competitive landscape. Investing in top-notch manufacturing processes not only benefits the end-users with durable and reliable packaging but also creates a more responsible and sustainable industry overall.

When choosing film roll packaging suppliers, there are several key factors to consider to ensure you are selecting the best option for your needs. As the U.S. flexible packaging market is projected to grow at a CAGR of 4.1% from 2024 to 2030, the demand for high-quality manufacturing solutions is also on the rise. Understanding the various packaging types, including pouches, bags, and roll stock, is crucial. The flexibility of these options can directly impact the efficiency and appeal of your product.

One important tip is to evaluate the printing technology used by potential suppliers. Flexography, rotogravure, and digital printing each offer unique advantages and may influence the final look and durability of your packaging. Additionally, consider the supplier's experience in heat sealing processes, as the integrity of seals can greatly affect the product's shelf life and overall quality.

Lastly, sustainability is becoming an essential factor in packaging decisions. A report on sustainable cosmetics packaging highlights the challenges and innovations in this area, urging companies to incorporate eco-friendly materials into their packaging solutions. Look for suppliers who prioritize sustainable practices and materials, as this not only benefits the environment but can also enhance your brand's reputation in a competitive market.

China has emerged as a formidable player in the global film roll packaging solutions market, leveraging its competitive edge in manufacturing. With a robust infrastructure and advanced technology, Chinese manufacturers produce high-quality packaging materials that cater to various industries worldwide.

The distinct offerings of cast wrap and blown wrap packaging highlight China's versatility, allowing businesses to select solutions tailored to their specific needs. This adaptability is key in an ever-evolving market landscape.

The film roll packaging sector is not only characterized by innovation but also by significant market participation from numerous players. The growing demand for efficient and sustainable packaging solutions has spurred strategic initiatives among companies, enhancing their market presence.

As competition intensifies, leading firms are focusing on expanding their capabilities and developing next-gen materials, such as polyethylene variants, to meet the diverse requirements of customers globally. As a result, businesses seeking reliable, high-quality packaging solutions turn to China, reinforcing the country’s reputation as a leading hub for packaging innovation.

The film roll packaging industry in China has made significant strides towards sustainable practices, driven by the growing demand for environmentally friendly solutions. According to a recent report by Smithers Pira, the global sustainable packaging market is projected to reach $500 billion by 2026, and China is set to play a pivotal role in this transformation. This shift is evident in the adoption of biodegradable materials and advanced recycling processes that minimize waste and reduce carbon footprints.

Additionally, many Chinese manufacturers are investing in innovative technologies to enhance the sustainability of their operations. For instance, a study by MarketsandMarkets indicates that the eco-friendly packaging segment is expected to grow at a compound annual growth rate (CAGR) of 5.7% from 2021 to 2026. Chinese companies are embracing solutions like water-based inks, compostable films, and reduced reliance on single-use plastics. This commitment not only meets the stringent environmental regulations but also aligns with the evolving preferences of conscientious consumers worldwide.

In parallel, the integration of circular economy principles into the film roll packaging supply chain is gaining traction. As reported by the Ellen MacArthur Foundation, the transition towards a circular economy could generate $4.5 trillion in economic benefits globally by 2030. Chinese firms are increasingly focusing on designing products that facilitate recycling and reuse, ensuring that film roll packaging solutions are both efficient and sustainable. This forward-thinking approach positions China as a leader in the quest for eco-friendly packaging innovations.

In recent years, China has been at the forefront of innovation in flexible packaging technologies, especially in film roll packaging solutions. The flexible packaging market, which includes a wide range of products such as pouches, bags, roll stock, films, and wraps, is projected to witness significant growth. According to industry reports, the flexible packaging market is expected to expand from approximately $250 billion in 2025 to around $300 billion by 2032, driven by increasing consumer demand for convenience and sustainability.

China's advancements in edge computing are playing a pivotal role in this transformation. Patent filings in edge computing have surged, showcasing the rapid pace of innovation within Chinese industries. This technological leadership not only enhances the quality and efficiency of manufacturing processes but also allows for smarter packaging solutions that can respond dynamically to consumer needs. In particular, innovations in printing technologies such as digital printing and flexography are revolutionizing the way brands approach packaging, enabling more cost-effective and customizable options. This shift is essential for companies looking to stay competitive in the global market, especially for environmentally-friendly packaging solutions that align with current consumer preferences.

| Packaging Type | Material Used | Dimensions (mm) | Production Capacity (units/day) | Innovative Technology |

|---|---|---|---|---|

| Stretch Film | LDPE | 500 x 300 | 10000 | Extrusion Coating |

| Blister Packs | PVC | 400 x 200 | 8000 | Forming Technology |

| Roll Wraps | BOPP | 600 x 150 | 12000 | High Speed Printing |

| Shrink Sleeves | PETG | 500 x 100 | 6000 | Heat Shrink Technology |

| Barrier Films | Multilayer | 700 x 300 | 4000 | Advanced Lamination |